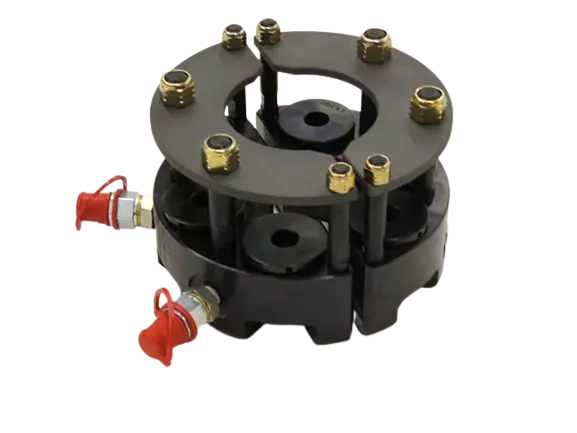

CamNut EziJac System

What is a CamNut EziJac System?

The CamNut EziJac system is a method to tension existing studs that do not have enough thread engagement above the hex nut. In normal applications, a bolt tensioning tool pulls on the bolt threads protruding above the regular hex nut, which is then screwed down to retain the loads induced by the hydraulic operation of the tool. If there is no available thread, the CamNut EziJac system performs as the connection to the bolt for the operation. Its integral collar expands to take up the bolt’s elongation under force and retains the load when the hydraulic charging pressure is released.

The revolutionary CamNut hydraulic tensioner brings an affordable and efficient solution in a compact system that is simple, safe, and easy to use.

To learn more about the CamNut hydraulic tensioner, contact us today!

Custom Engineered Tensioners Since 1986

HTI has been designing engineered solutions to your toughest bolt tensioning problems since 1986! You can choose from one of our standard catalog sizes above, or we can design a custom fixed tensioner for any application when a standard model won’t work. HTI tensioners can be designed for imperial or metric-sized studs, high loads, high temperatures, large stud sizes or corrosive environments. Our multi-unit tensioning systems can make easy work of large bolted systems, and our automated tensioning systems can reduce labor and increase throughput in high-volume manufacturing applications.

Similar Products

Multi-Stage Tensioners

Learn More

Foundation Tensioners

Learn More

Through-Hole Tensioners

Learn More

Variable Tensioners

Learn More

High Load & High Stroke Hydraulic Tensioners

Learn More

Multi-Unit Tensioners

Learn More

Large Stud Diameter

Learn More

Flange Tensioners

Learn More

Subsea Tensioners

Learn More

Wind Turbine Tensioners

Learn More